SHIPDEX IS

making maintenance,

and related processes, much easier.

As equipment onboard ships gets more and more complex and sophisticated, so does the work of maintaining it. Maintenance tasks need to follow precise instructions, use precise spare parts. Just like maintaining a modern car, compared to doing it 20 years ago. And that means people doing the maintenance work, and spare part ordering, need to have very quickly and exactly the right information they need.

This information is provided by the shipyards and equipment manufacturers, but up to now, it has been provided on paper or in pdf format. Such kind of information needs to be either photocopied and filed, or retyped into IT systems (ERP, CMMS, etc.). It is very easy important instructions and data to get lost, or full of errors. Technical information in Shipdex format means to get “electronic and standardized information instead of pages of information (in paper or pdf format)”

Shipdex is a non-proprietary, open data standard way to get electronic data about descriptive, operational, maintenance instructions and related spare parts catalogues from the equipment manufacturer or shipyard, to the computer systems which are used by seafarers and purchasing managers, to manage the maintenance and purchasing. As an open standard, nobody profits or controls it. It is based on the standard S1000D used in aviation and defence sector for over 30 years.

History

The reason to develop a common and standardized Protocol for exchanging data resides on the fact that shipping companies were receiving from manufacturers technical manuals in different formats, different structures and different data quality.

This situation created several troubles to end users in terms of information comprehension and electronic usage.

For instance, end users need to store paper manuals in dedicated rooms or are obliged to use different viewers (or browsers) to visualise electronic manuals supplied in HTML, WORD, XML or PDF formats.

Moreover, since most shipping companies are utilizing Computerized Maintenance Management Systems (CMMS) and Enterprise Resource Planning (ERP) software applications to manage and optimize maintenance and material purchase processes, a standard data exchange protocol allowing databases automatic generation was deemed necessary. Therefore the Shipdex™ protocol is dealing with technical information and the technical manuals must be considered just as one of the possible output from a Shipdex™ dataset.

In 2007 – 2008 a group of ship-owners, manufacturers and an IT company organized some meetings to confirm the will to develop a common and shared Data Exchange Protocol whose name was decided to be Shipdex™. All the former Founder Members companies agreed to develop the “Shipdex™ Data Exchange Protocol”.

The very first Shipdex 1.0 issue was released in 2008.

Scope

Shipdex™ Protocol covers technical data exchange in any sea projects.

This means that Shipdex Protocol is open to any company/organization which wishes to use it and can be implemented by anyone on different Information Technology systems. Information produced in accordance with Shipdex™ Protocol is achieved in a modular form, called “Data Module”, which is defined as “the smallest self-contained information unit within a Shipdex™ dataset”. Shipdex™ Protocol defines Data Modules as containers for data exchange. The Shipdex dataset is the collection of all the information (data modules, information objects and external documents) related to a given product in a given configuration.

A Data Module contains the following kind of information:

- An identification and status section with all identification and quality assurance information

- A content section, which is different, depending on the Data Module type.

The Data Module types that Shipdex™ Protocol makes use are:

- Descriptive and operational

- Procedural

- Spare parts, support equipment and consumables catalogues (IPD)

- Troubleshooting

- Maintenance Planning

- Publication

- Comment

- SCO content

- Learning

- SCO Content Package Module (SCPM)

The above Data Module types are governed by the following S1000D™ issue 2.3 xml schemas:

- Descript.xsd (Descriptive, operational and troubleshooting)

- Proced.xsd (procedural)

- ipd.xsd (Illustrated parts data)

- schedule.xsd (Maintenance Planning)

- pm.xsd (Publication)

- comment.xsd (Comment)

and by the following S1000D issue 4.2 xml schemas:

- scocontent.xsd (SCO content)

- learning.xsd (Learning)

- scormcontentpackage.xsd (SCO Content Package Module)

- lom.xsd (to be used to validate SCPM data modules)

available for a free download on www.s1000d.org

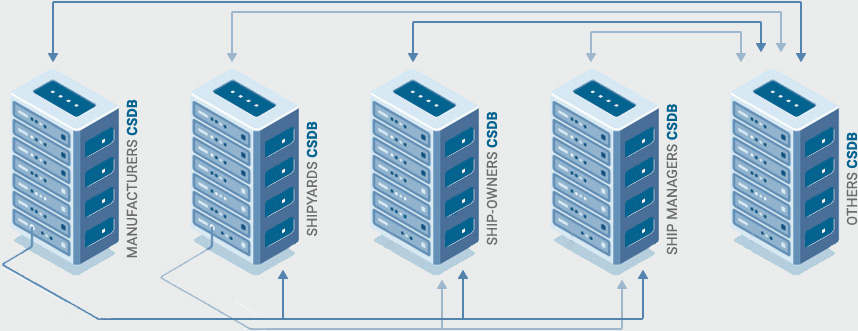

All Data Modules that are applicable to different Products may be gathered and managed in a database, which is hereafter referred to as the Common Source DataBase (CSDB).

Information is not duplicated in the CSDB though individual Data Modules can be used many times in the output. Savings are therefore made in the maintenance of the data in that it only needs to be changed once, whilst the changed information appears throughout the outputs.

Main Benefits

- Data interoperability at data level, through use of schemas etc.

- Non-proprietary specification and based on open standards

- Ease of data exchange, using small xml based files structures

- Possibility to add extra documentation features such as Link mechanisms etc., enabling better end user experience

- Focused to produce objects of information, instead of the traditional paper bound constraints

- Enabled to focus specifically on data data

- Layout is not included in Shipdex dataset

Authoring benefits

- Re-use of data (in a modular format) allows to save up to 40% of data production time

- Reduction in update costs, due to use of data module concept of up to 30%

- Module Uniqueness (Task /Description), allows task orientated definition

- Compliant Authoring tools available, multiple vendor support

Life Cycle benefits

- Reduced creation and update costs, thanks to data re-use

- Lower document distribution costs, multiple methods of delivery available

- Wider access and more efficient retrieval of the documentation by the end user, multiple methods of delivery available

- Easy filtering of information through the Common Source DataBase (CSDB)

- Increased operational readiness through reduced MTTR, through more focused maintenance

- Increase in data integrity and the generation of better quality documents, through data integration and data module concept

Common Source DataBase (CSDB)

This is the “store” where Shipdex data should be stored. CSDB is the most important technical documents repository where all the Shipdex data can be stored together with all the updates. Applying filters it is possible to retrieve required information that can be used to:

- Export towards other IT systems (ERP, PMS, etc)

- Produce Shipdex datasets

- Publish selected data in the form of pdf manuals or Interactive Electronic Technical Publications (ERP)

- Publish SCORM compliant CBTs

However Shipdex does not define its functionalities. Shipdex just recommend that there is a requirement to hold and manage the data modules produced in Shipdex format.